Machine Tool Series

CNC compound grinding machine is a kind of CNC grinding machine mainly used for grinding all kinds of transmission parts. This machine adopts the 6-axis 3-linkage CNC system of Fage Company and can produce all kinds of enveloping worm with the special processing software of worm developed by our company.

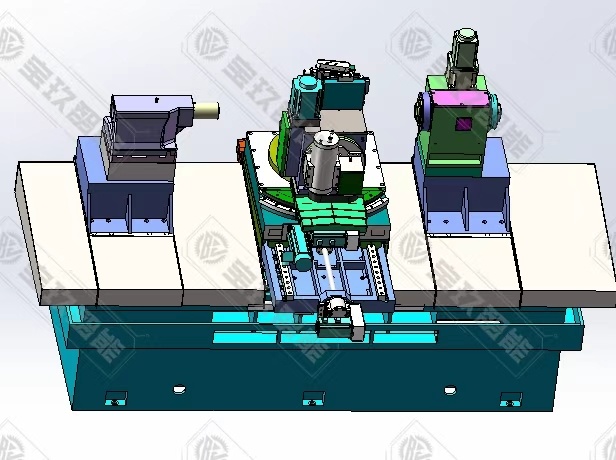

Multi-axis linkage compound machine tool, multi-functional worm grinder, compound worm machine tool

This machine tool is a CNC multi-axis precision composite machine with dual milling and grinding capabilities. Equipped with a FAG 9-axis 5-axis CNC system and customized worm gear machining software, it offers extensive processing adaptability. Its primary machining scope includes: various cylindrical worms with a maximum center distance of 350mm, and various cylindrical worms with a maximum workpiece diameter of 100mm. This encompasses normal straight-flank worms (ZN), axial straight-flank worms (ZA), involute worms (ZI), conical enveloping worms (ZK), and circular cylindrical worms (ZC). Additionally, the machine can perform milling or precision grinding of lead screws and threads, as well as form machining of complex components like screws, splines, and gears, fully demonstrating its multifunctional composite processing capabilities.

CNC650 enveloping worm gear machine, worm grinder, high-speed worm milling

The CNC650 CNC enveloping worm gear dedicated machine tool is a CNC machine tool mainly used for machining enveloping worm gears. This machine tool uses a 6-axis 3-联动 CNC system from Fagor, and with our company's self-developed dedicated worm gear processing software, it can produce various enveloping worm gears. By changing the corresponding turret, grinding head and milling head, the workpiece can be turned, ground and milled accordingly.

BCNC500 Multifunctional CNC Compound Grinding Machine

The BCNC50 multi-functional CNC compound grinder is a CNC grinder mainly used for grinding and machining various gear shapes of transmission components. This machine tool uses a CNC system from Fagor, has a high degree of autonomy, and can be further developed according to the actual needs of customers.

Roll grinder

Roll grinders are key equipment in high-precision manufacturing. Through precise structures, automated control, and advanced grinding technology, they provide reliable processing solutions for industries such as bearings, aerospace, and automobiles. With the advancement of intelligent manufacturing, roll grinders are developing towards higher efficiency, greater intelligence, and better adaptability to complex materials, further promoting precision upgrades in manufacturing.

Internal hole and internal surface grinding machine

Internal and internal surface grinding machines, as important tools in the field of precision manufacturing, play a significant role in improving the overall level of China's manufacturing industry through technological advancements and application expansion. In the future, with the in-depth implementation of intelligent manufacturing and green manufacturing concepts, internal and internal surface grinding machines will develop towards higher precision, higher efficiency, and greater intelligence, contributing to the high-quality development of China's manufacturing industry. At the same time, in the face of the new situation of international competition, strengthening independent research and development, breaking through key technologies, and improving the international competitiveness of domestically produced grinding machines are also urgent tasks for the industry's development.