Grinding head (electric spindle type)

Keywords:

Product Description

The main functional components of the machine tool include: spindle box assembly, tailstock assembly, rotary table assembly, grinding head, milling head, etc.

This grinding head is driven by an electric spindle, and its main moving mechanisms include the grinding head column, the grinding wheel angle adjustment mechanism; the A-axis clamping mechanism; the grinding wheel compensation mechanism; the grinding wheel dressing mechanism; the grinding wheel drive mechanism (grinding wheel); the base circle adjustment mechanism and the grinding head rotating radius adjustment mechanism, etc. The grinding wheel working plane coincides with the rotating axis of the grinding head column (grinding wheel centering).

Details are as follows:

1. Grinding wheel angle adjustment :

This grinding head uses a manual adjustment mechanism for the grinding wheel angle. The rotating structure uses a high-precision backlash-eliminating worm gear pair. Measurement uses a grating ruler to display the grinding wheel angle, ensuring the final grinding wheel angle accuracy.

2. A-axis clamping:

The A-axis clamping mechanism uses a normally closed clamping mechanism. Under normal circumstances, the clamping mechanism is in the clamping state. When adjusting the grinding wheel angle, the hydraulic system is activated to release the clamping mechanism. After the grinding wheel angle adjustment is completed, the clamping mechanism clamps the A-axis to ensure the grinding wheel angle is stable, accurate, and reliable.

3. Grinding wheel compensation:

The grinding wheel compensation mechanism is automatic. The structure uses a high-rigidity, high-precision rolling guide rail. A grinding wheel axial compensation moving device is installed between the grinding wheel and the flange, driving the grinding wheel to move along the grinding wheel axis direction to achieve grinding wheel dressing compensation.

4. Grinding wheel dressing:

The grinding wheel dressing mechanism is automatic and uses a diamond stylus at the end of the dressing rod to dress the grinding wheel. The grinding head column front flange has a grinding wheel installation datum surface. The grinding wheel installation and diamond stylus installation can adjust the correct position of the diamond stylus through the datum surface.

There is a reliable sealing protection device at the outlet of the dressing rod to prevent grinding dust and coolant from affecting the dresser.

Main technical parameters:

- Grinding head column center height: 210mm;

- Grinding wheel diameter: 250mm (can be increased to 280);

- Grinding wheel working angle (mother plane inclination angle): ±30°;

- Dresser diamond stylus dressing stroke: 60mm;

- Grinding wheel compensation limit size: 20mm;

- Grinding wheel single compensation amount: 0.05mm (adjustable);

- Grinding wheel linear velocity: 30m/s-60m/s;

- Grinding wheel motor: high-precision, high-power electric spindle;

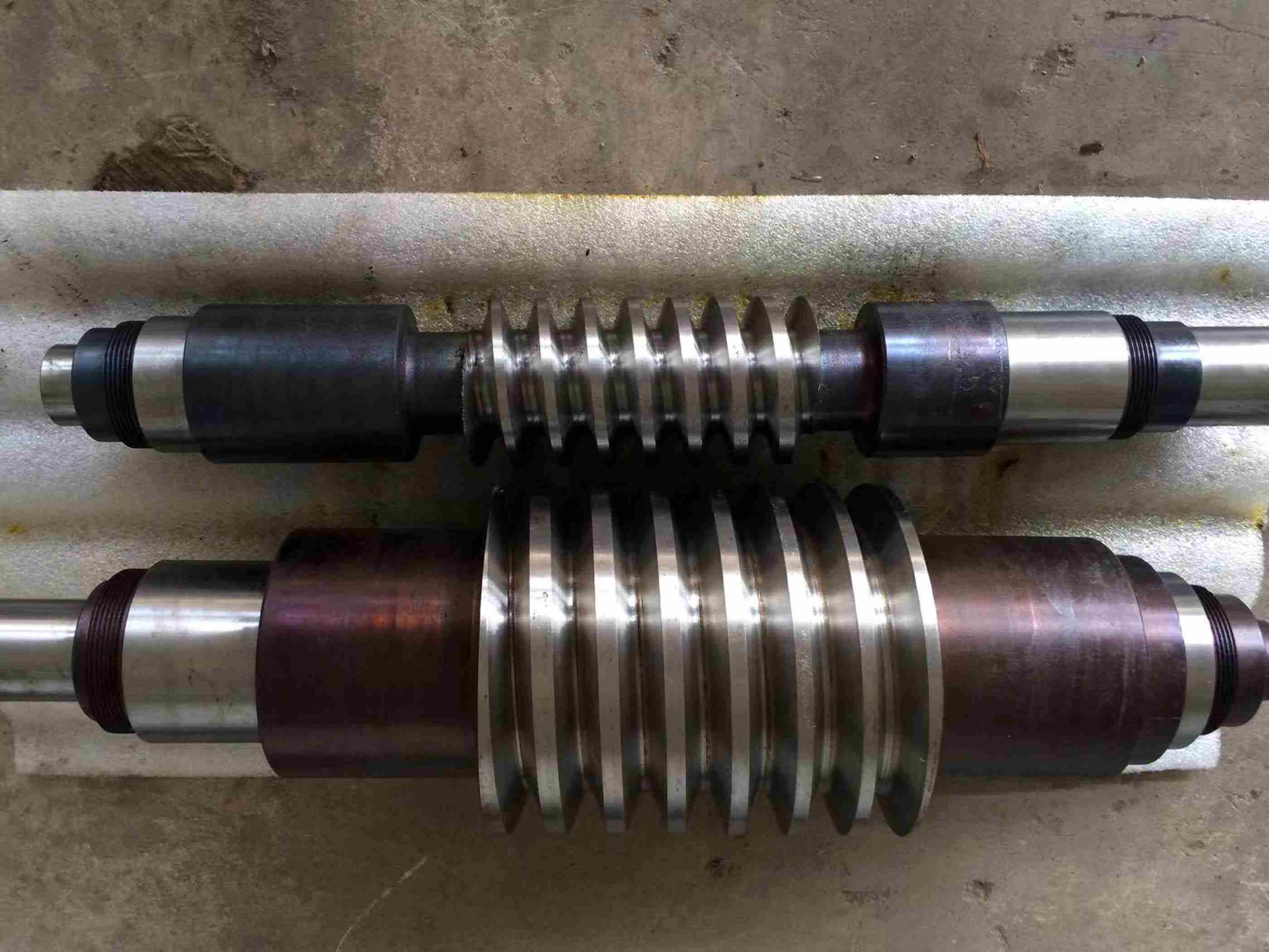

- Can grind double-enveloping worm workpiece center distance, 80-800 (for some machine tools, the size limit of the ground workpiece varies due to structural limitations).

Baoji Yi Jiu Mechanical Equipment Co., Ltd.

October 17, 2024

Classification:

Machine tool functional components